Wholesale Electric Motorized 3-Way Brass Ball Valve with Electric Actuator - 12V, 24V, 220V Options for Flow Control - OEM/ODM for Brand Partners

Wholesale Electric Motorized 3-Way Brass Ball Valve with Electric Actuator - 12V, 24V, 220V Options for Flow Control - OEM/ODM for Brand Partners

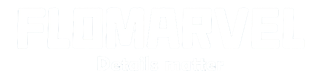

Motorized diverter valves offer a wide range of benefits in industrial applications, from increased productivity and cost savings to improved safety and reduced downtime. Their versatile functionality and durability make them an invaluable asset for companies aiming to unlock efficiency in today's competitive landscape.

By incorporating motorized diverter valves into their operations, companies can achieve seamless switching between different flow paths, allowing for greater control and flexibility in their processes. With the ability to redirect materials, reroute flow, or change the course of production swiftly and precisely, these valves save time, reduce operational costs, and optimize resource utilization.

Furthermore, motorized diverter valves contribute to improved safety measures by ensuring reliable redirection of materials and reducing the impact of downtime through quick and precise adjustments. Their applications span across various industries, including food and beverage, chemical, pharmaceutical, and oil and gas, where they enhance efficiency and productivity.

When selecting motorized diverter valves, factors such as flow capacity, durability, control options, and maintenance should be considered. Proper installation and regular maintenance are essential to ensure optimal performance and longevity.

Investing in motorized diverter valves is a strategic decision that can lead to enhanced efficiency, increased productivity, and improved overall performance in industrial applications. With their robust construction, precise control, and versatile functionality, these valves are undoubtedly a game-changer for industries striving to stay ahead in today's competitive landscape.

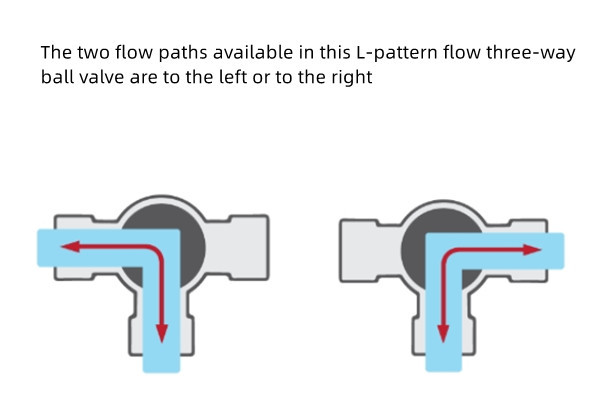

D1/D2 | DN | φd | L1 | L2/L3 |

F

|

H1

|

H2

|

Weight (KG)

|

1/4'' | DN8 | 8 | 45 | 10 |

21

|

68

|

42

|

0.25

|

1/2'' | DN15 | 15 | 57 | 11 | 25 | 71 | 42 | 0.31 |

3/4'' | DN20 | 20 | 63 | 12 |

31

|

74

|

42

|

0.40

|

1'' | DN25 | 25 | 73 | 16 |

37

|

77

|

42

|

0.51

|

Series | Torque | Operating time | Working voltage |

Working current

|

Max. power

|

Max. pressure

|

FH | 2.5 N.M | <5S | 3-6V DC, 9-24V ADC, 110-230V AC |

<100 mA

|

5W

|

1.0 Mpa

|

Medium temperature | Ambient temperature | Humidity | Enclosure |

Service life

|

Wiring |

|

0-100℃/32-212℉ | -20-45℃/-4 -113℉ | 95% | IP67 |

50,000 - 80,000 times

|

OP01, OP02, OP03, OP04, OP05 optional, customization available |

- Loading...

- Tel

- *Title

- *Content

- How to place an order for our motor ball valve?

-

- 1. Confirm the specifications of the electric motor ball valve needed.

- 2. We offer an quote for the product and the shipping cost if needed.

- 3. Make a Proforma invoice for payment, if the quote is accepted.

4. Start production and update shipping information after shipment.

5. After-sales service if needed.

- Tel

- *Title

- *Content