Home / All / 2.5NM mini motorized ball valve / Electric brass ball valve /

Electric Actuator Mini Motorized Ball Valve in Stainless Steel & Brass - 1/2, 3/4, 1 Sizes and more - 5V, 12V, 24V, 110V, 230V OEM/ODM Solutions for Wholesale and Distributor Partnerships

Electric Actuator Mini Motorized Ball Valve in Stainless Steel & Brass - 1/2, 3/4, 1 Sizes and more - 5V, 12V, 24V, 110V, 230V OEM/ODM Solutions for Wholesale and Distributor Partnerships

Detail Information

Automatic ball valve

Features

∎ Precision metal gear, high strength, reliable performance, long service life

∎ Multiple wiring for remote control and valve status feedback to intelligent control unit

∎ Floating sealing ball valve, no leakage

∎ Low power consumption, battery workable

∎ Flame retarded PC-ABS enclosure with compact, exquisite structure for small equipment

∎ IP 67 protection, applicable for humid environment

∎ With visual position indicator

∎ Various connectors customizable

∎ Manual override available for option

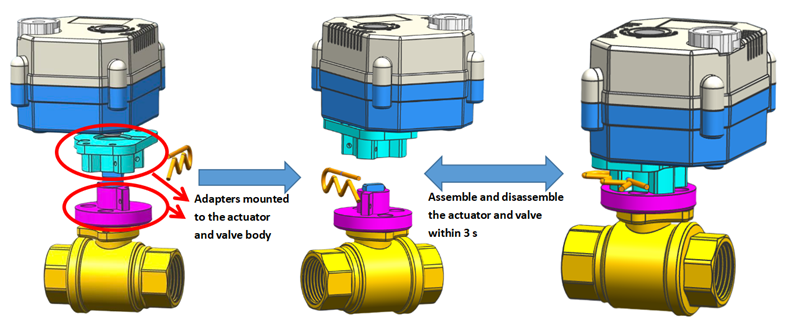

Clip-Pin connection of electric actuator and ball valve

What is great about the clip-pin connection?

With adapters assembled to the electric motor actuator and ball valve, the actuator and ball valve can be assembled and disassembled in seconds, which makes:

① installation much easier. When the mounting space is limited, install the ball valve on the pipe first and then mount the electric actuator on to it will make the process much easier.

② repairing much less troublesome. When there is a malfunction, mostly only need to change or repair the actuator, with this design, it won't be necessary to stop the whole system to take off the whole set of valve off the pipe, taking off the actuator to replace with a good one will minimize the affect of a part failure. ③ tremendous reduction in inventory for retailers, for whom stock valve of various specifications, instead of stocking whole set of electric ball valve, seperately stock electric actuator and ball valve would make inventory much more flexible.

Application

Electrically motor operated water shut off valve - widely used in water treatment systems, home automation, HVAC system, irrigation system, wildfire emergency sprinkler system, recreational vehicle (RV), trailer home, sprinkler truck, fire truck, air compressor, washing machine, etc., where automatic remote fluid control is needed.

Factors to consider when choosing a ball valve motorization system

When selecting a ball valve motorization system, it is essential to carefully evaluate a range of factors to ensure that the chosen solution meets your specific needs and requirements. By considering these key factors, you can make an informed decision and maximize the benefits of ball valve motorization in your operations.

One of the primary considerations is the application and operating environment. Different industries and applications may have unique requirements in terms of size, pressure, temperature, and flow rate. It is crucial to select a ball valve motorization system that is designed to withstand the specific conditions of your application, ensuring reliable and long-lasting performance.

Another important factor is the required level of control and responsiveness. If your application demands precise flow regulation or rapid response times, you may need to choose a more advanced motorization system with features like variable speed control, position feedback, or high-speed actuation. Conversely, if your requirements are more basic, a simpler, cost-effective solution may be sufficient.

The integration and compatibility of the ball valve motorization system with your existing infrastructure is also a critical consideration. Ensure that the chosen system can seamlessly integrate with your current control systems, communication protocols, and power sources, minimizing the need for extensive retrofitting or custom modifications.

Additionally, factors such as energy efficiency, maintenance requirements, and the overall life cycle cost of the system should be carefully evaluated. Choosing a ball valve motorization system that aligns with your sustainability goals, operational budgets, and long-term maintenance strategies can have a significant impact on the overall return on investment and the total cost of ownership.

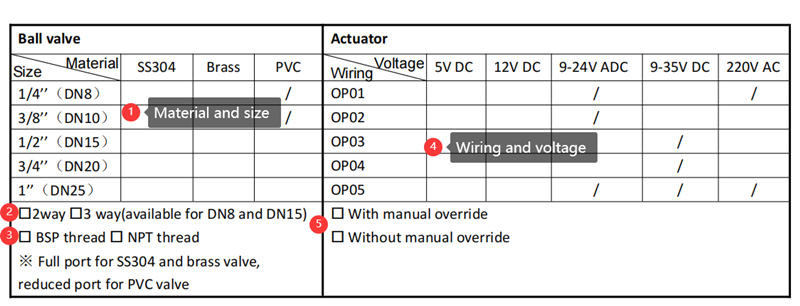

Purchase guide of motor operated ball valve

When Purchasing An Electric Motor Ball Valve, It Can Be Intimidating To Decide All The Specifications All At Once. Below Form Should Help To Simplify The Process. Click for more details.

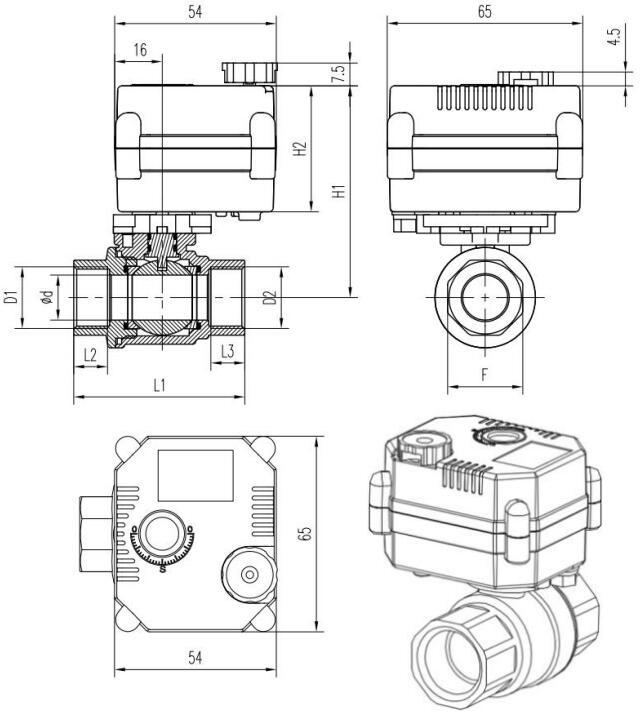

Dimension

D1/D2 | DN | φd | L1 | L2/L3 |

F

|

H1

|

H2

|

Weight (KG)

|

1/4'' | DN8 | 8 | 45 | 10 |

21

|

68

|

42

|

0.25

|

1/2'' | DN15 | 15 | 57 | 11 | 25 | 71 | 42 | 0.31 |

3/4'' | DN20 | 20 | 63 | 12 |

31

|

74

|

42

|

0.40

|

1'' | DN25 | 25 | 73 | 16 |

37

|

77

|

42

|

0.51

|

Unit: mm

Technical parameters

Series | Torque | Operating time | Working voltage |

Working current

|

Max. power

|

Max. pressure

|

FH | 2.5 N.M | <5S | 3-6V DC, 9-24V ADC, 110-230V AC |

<100 mA

|

5W

|

1.0 Mpa

|

Medium temperature | Ambient temperature | Humidity | Enclosure |

Service life

|

Wiring |

|

0-100℃/32-212℉ | -20-45℃/-4 -113℉ | 95% | IP67 |

50,000 - 80,000 times

|

OP01, OP02, OP03, OP04, OP05 optional, customization available |

Certifications

Factory

Manufacturer sepcialized in motorized ball valve, ODM/OEM available, best price.

Why choose us

Review

- Loading...

Contact Us Now

If you would like to know more about our products and services, complete the form below, and we will contact you as soon as possible to discuss your requirements.

- Tel

- *Title

- *Content

- How to place an order for our motor ball valve?

-

- 1. Confirm the specifications of the electric motor ball valve needed.

- 2. We offer an quote for the product and the shipping cost if needed.

- 3. Make a Proforma invoice for payment, if the quote is accepted.

4. Start production and update shipping information after shipment.

5. After-sales service if needed.

Contact Us Now

If you would like to know more about our products and services, complete the form below, and we will contact you as soon as possible to discuss your requirements.

- Tel

- *Title

- *Content